Asia-Pacific Biologics CMO Facilities

$1,999.00

Access in-depth research and analysis of key Biologics Contract Manufacturers operating in key Asian markets – China, Taiwan, Korea, Japan, Southeast Asia, India and Australia.

- Description

- Additional information

Description

- Overview

- Scope

- Benefits

- Key Questions Answered

- Data Methodology

- Table of Contents

- Figures & Tables

- User Access

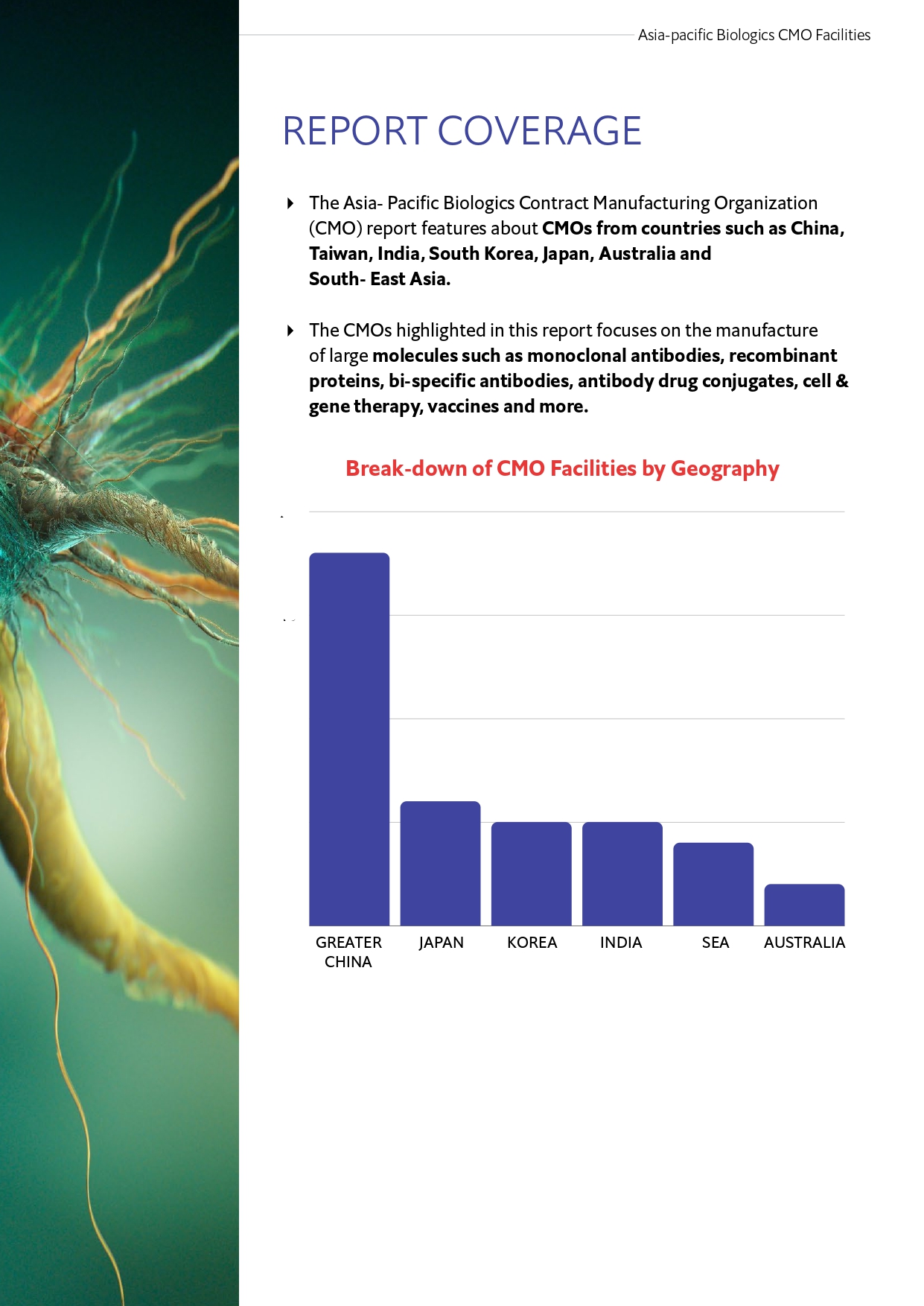

Asia-Pacific Biologics CMO Facilities report features data analysis of companies manufacturing large molecules such as Monoclonal Antibodies, Recombinant Proteins, Cell Therapy, Bi-Specific Antibodies, Vaccines and more. The report covers the following regions: China, South Korea, Japan, Taiwan, India, Singapore, Australia, and SEA. It sheds light on the facility design, services offered, bioprocessing technologies currently used across the manufacturing value chain (starting from cell-line development until fill & finish), plant capacity, facility type (single-use vs stainless steel) and facility investment.

The report provides insights on the following topics but not limited to:

Scale of manufacturing of Biologics Facilities

Manufacturing services provided by CMOs

Products manufactured and projects completed

Team- distribution

Plant capacity and facility size

Facility investment

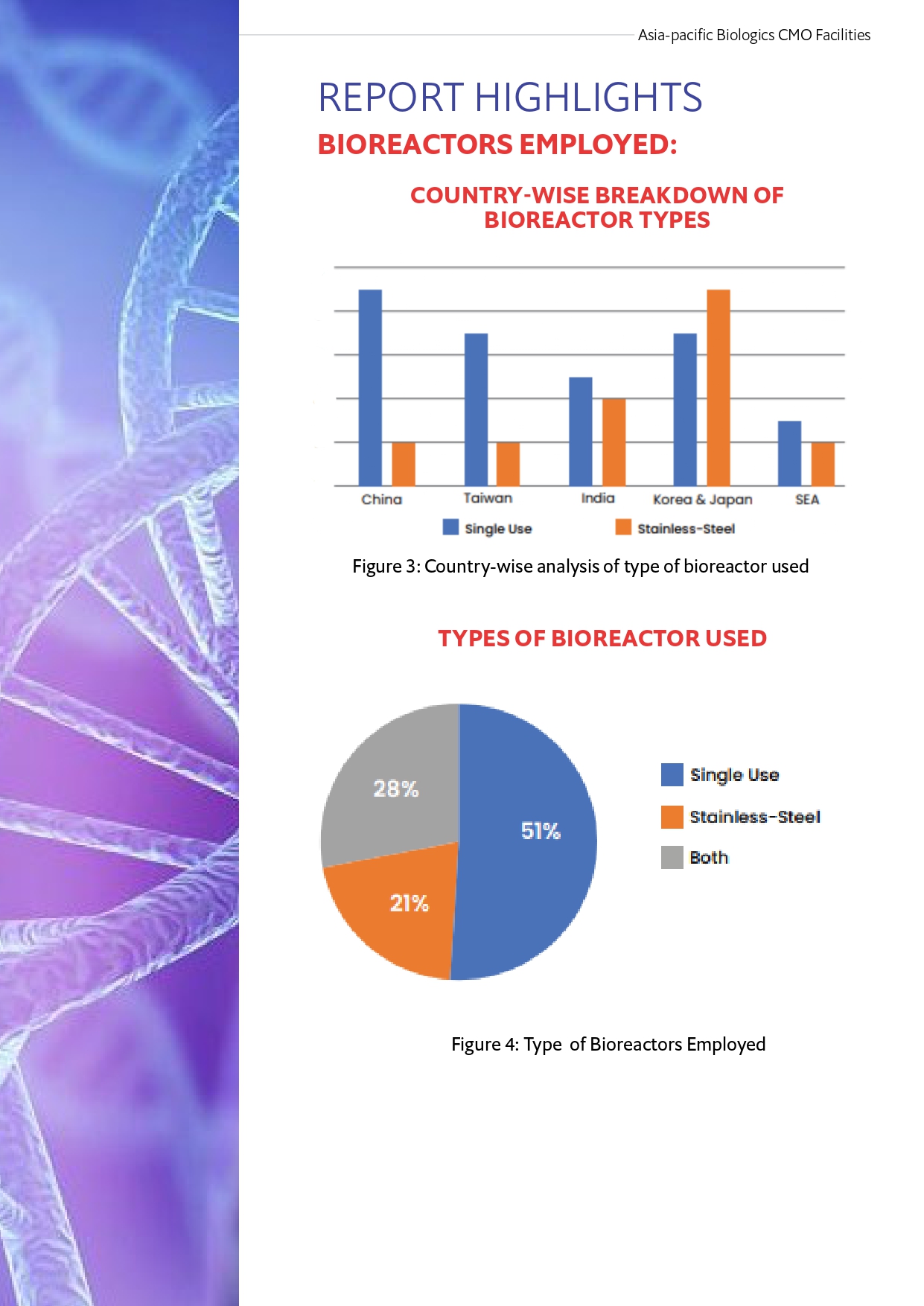

Batch Size and type of bioreactors used

Facility design

Process technologies employed in facility

GMP certifications

Future expansion plans of CMOs

The first and second section of the report presents preface and executive summary. It enlists the major topics covered in the report.

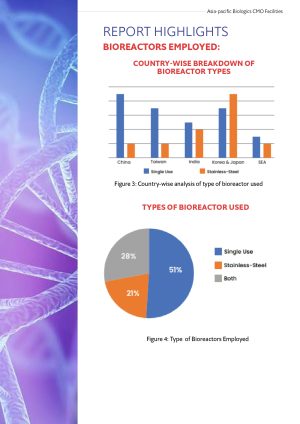

The third section provides detailed qualitative and quantitative analysis of the CMO’s in the APAC region such as bioreactors employed, process technologies used, team-distribution, regional wise analysis of the expression systems, GMP certifications, facility investments, size and so on. For instance, the analysis reveals that in the APAC region, China is currently taking a lead in the Single-use systems while CMO’s in Korea such as Binex, Samsung BioLogics and Hanmi has either a hybrid facility or a full-stainless steel facility. Some of the reasons associated with such usages are covered in the sections that follow.

Majority of the CMOs discussed in this report have employed batch or fed-batch processes. However, closer look at those companies show that they are moving towards adapting continuous processing manufacturing technologies as part of their future expansion plans. Moreover, some companies have both processes to offer depending on the product type of their clients.

The fourth section has expert poll and survey analysis which studies respondent profiles, CMO’s brand perception as voted by Biopharma companies, and other significant points of consideration for Biopharma organizations. The respondent analysis with figures and charts on the job title, stage of production and manufacturing capabilities can be found in this section.

The fifth section of the report has detailed highlights and features of biopharma contract manufacturers of Asian countries. It provides brief data on CMO services, facilities and products in manufacturing.

The last section of the report includes comprehensive research-based data on biologics CMOs from greater China, India, Korea, Japan, Southeast Asia and Australia. It includes data on several parameters such as manufacturing services provided by CMO and their Pricing, competitiveness, plant capacity & batch size of each CMO facility, products manufactured and projects completed by CMO, GMP & quality certifications of CMO facilities, employee breakdown and financial insights, partnerships & collaborations and future expansion plans of each CMO.

The option to customize the report is available upon request to meet your data requirements for example any specific country or market data from SEA market. The customized report is comparatively cost-effective and dependent on data requirements.

The CDMO market in APAC has been steadily growing in the recent years. More companies are bringing their products into the clinical trials phase and are choosing to out-source to a full-service CDMO rather than several niche providers. Many pharmaceutical companies are out-sourcing their manufacturing to service providers to reduce costs and make use of the technologies that manufacturers are developing, which they might not have access to.

Within the scope of the report, IMAPAC Pte Ltd has performed an analysis of the CMOs in the region to highlight the various services provides and trend of technologies used in the biomanufacturing. The study focuses on the various Contract Manufacturing Organisations in Asia. This includes companies from China, Taiwan, Korea, Japan, India, SEA and Australia.

Following the trend in the APAC CMO market, biotech and pharmaceutical companies are opting for CMO services to speed up their development process and lower the production costs. In 2019, the biologics segment held the largest market share in the biopharmaceutical contract manufacturing market in Asia Pacific. With that in consideration, the report includes meaningful insights to enable biopharma and pharmaceutical companies to understand the CMO market landscape in Asia through detailed analysis of the various contract manufacturers who are operating in the region since 2005.

The report reveals that greatest number of plants were built in 2019. Further, the insights in these reports are valuable for CMOs or CDMOs as well, to understand their competitors’ facilities better in terms of the services offered, plant capacities, future expansion plans and so on.

IMAPAC Pte. Ltd. has released this report with an objective to support key industry stakeholders in the biologics manufacturing through strategic collaboration with contract manufacturing organizations for outsourcing manufacturing activities or gain deeper understanding of CMO facilities across APAC.

Asia-Pacific Biologics CMO Facilities Report with more than 290 page consists of 113 tables and 91 figures that are easy to comprehend. This report presents key details on the top Biologics CMOs in the APAC Market, analyses data based on primary research such as projects completed, pricing competitiveness, investments, clients, future expansion plans and much more.

This report is unique in that our charts and analyses figures are based solely on data collected directly from the biopharma and big pharma on the various CMOs of their choice in each region. The survey respondents’ companies are either currently manufacturing their products in- house or outsourcing their manufacturing activities to a CMO. Read on to know more about the various service providers and technology trends used in the manufacturing. This report lets you understand CMO’s facilities better.

Through this report, you are more likely to stay ahead of your competitors and expand your knowledge and expertise in biomanufacturing. Identify co-development and other business-related partnerships, to plan future portfolio focus and to invest in research and technologies to fill the gaps identified.

This report may potentially help your research, analyses, and strategic decisions. IMAPAC’s Report is intended for anyone who demands comprehensive and in-depth analyses for Biopharma contract manufactures in key Asian markets.

- Which is the largest facility in Asia for biologics clinical or commercial manufacturing?

- Which CMO is preferred highly by the Biopharma or pharmaceutical companies in Asia?

- What are the manufacturing services provided by the CMOs?

- Which key products are manufactured in CMO’s facility?

- How many projects are completed and the breakdown of stages for each manufactured product?

- Which drug substance and drug manufacturing projects are completed in each facility in Asia?

- What are the bioreactor capacities in each facility, process development labs and DPM sites? Is the capacity expandable?

- How does CMOs evaluate pricing compared to their competitors in Asia?

- What are the key factors of consideration for Biopharma companies while selecting the CMOs?

- Which are the key existing clients of CMOs and their client distribution regionally?

- What is the strength of manufacturing team?

- What type of equipment and technologies are used by CMOs and what is the unique selling point?

- Who are the current investors in each CMO facility and their plans to seek investment?

- What are the future expansion plans for CMOs in Asia?

The data in this report is researched and validated using primary and secondary research. The data is collected through multiple scientific and non-scientific sources including live discussions with experts through IMAPAC’s events and research reports, company websites, press releases, publicly available information, regulatory database and many more.

Preface

Executive Summary

CMO Landscape in APAC

Report Scope

Regional Analysis of the Bioprocessing Facilities

Year of Establishment of Facility

Bioreactors Employed

Process Technologies Employed

Expression Systems

Services Offered

GMP Certifications

Facility Investment

Pricing Competitiveness

Facility Size

Scale of Manufacturing

Employee Distribution

Expert Poll & Survey Analysis

Respondent Profiles

CMO Brand Perception- Voted by Biopharma

Points of Consideration of Biopharma

CMO Highlights

CMO Facilities in Greater China

Amaran Biotech

Boehringer Ingelheim

Chime Biologics

Cmab Biopharma

Eirgenix

Innovent Biologics

Jhl Biotech

Lonza (China)

Mabplex

Mycenax

Obio Technology

Sinobioway (Pku Biologics)

Sunshine Guojian (3s Bio)

Taron Solutions

Unicocell

United Biopharma

Wuxi Atu Co., Ltd

Wuxi Biologics

CMO Facilities in India

Enzene Biosciences Ltd

Intas Pharma

Kemwell Biopharma

Stelis Biosource

Syngene

CMO Facilities in Korea

Binex

Eubiologics

Hanmi Pharma

Kolon Life Sciences

Samsung Biologics

CMO Facilities in Japan

AGC Biologics

Ajinomoto Pharma Services

Hitachi

ID Pharma

Medinet

Takara Bio

CMO Facilities in South-East Asia

Esco Aster

Lonza AG Singapore

PT Kalbio Global Medika

TCels

CMO Facilities in Australia

Cell Therapies Pty Ltd

Luina Bio

List of Tables

Table 1: Services offered by CMOs in China

Table 2: Services offered by CMOs in Taiwan

Table 3: Services offered by CMOs in India

Table 4: Services offered by CMOs in Korea and Japan

Table 5: GMP Certifications received by the CMOs

Table 6: Scale of manufacturing for the CMOs featured

Table 7: Facility highlights of Boehringer Ingelheim

Table 8: Facility highlights of Chime Biologics

Table 9: Different components of facility in Chime Biologics

Table 10: Wuhan Facility Overview: Chime Biologics

Table 11: Details of bioprocessing equipment, model of equipment, & solution providers of Chime Biologics’s manufacturing facility

Table 12: Facility highlights of CMAB

Table 13: Facility Highlights of Hsinchu Biomedical Park, Zhubei: Eirenic

Table 14: Bioprocessing equipment in Eirgenix’s mammalian cell culture facility

Table 15: Bioprocessing equipment in EIrgenix’s microbial fermentation facility

Table 16: Break-down of the bioprocessing facility in Eirgenix

Table 17: Product pipelines of Eirgenix

Table 18: Future expansion plans from stage 1, 2 and 3 of Eirgenix

Table 19: Facility highlights of Innovent Biologics

Table 20: Product pipeline of Innovent Biologics

Table 21: Facility overview and highlights of JHL Biotech

Table 22: Management Team of JHL Biotech

Table 23: Summary of bioprocessing equipment models and the solution providers associated with JHL Biotech manufacturing facility

Table 24: Facility highlights of Lonza (China)

Table 25: Facility highlights of Mabplex

Table 26: Production capabilities by size of Batch of MabPlex

Table 27: Linkages, linkers and payloads offered by MabPlex

Table 28: Facility highlights & overview of Mycenax

Table 29: Capacity and Batch Size for both the liquid and lyophilised form

Table 30: Technology platform in Mycenax’s bio-manufacturing facility

Table 31: Highlights of plant capacity: Mycenax

Table 32: Mycenax Biomanufacturing Plant Highlights

Table 33: Details of current aseptic filling line in Mycenax facility

Table 34: Product pipelines of Mycenax

Table 35: Product Pipeline: Mycenax

Table 36: Breakdown of Projects completed

Table 37: Facility highlights of Obio technology

Table 38: Facility highlights of Sinobioway

Table 39: Production line facilities and their batch sizes; 3S Bio

Table 40: Preparation filing line and the capacities; 3S Bio

Table 41: Facility highlights of Taron Solutions

Table 42: Facility highlights of Unicocell

Table 43: Bioprocessing tools and equipment used and their solution providers; Unicocell

Table 44: Facilities overview and highlights of United Biopharma

Table 45: Overview of 3 plants of United Biopharma

Table 46: Types of bioreactors in Plant in Taiwan

Table 47: Types of bioreactors in Plant in Yangzhou

Table 48: Overview of R&D Centre and Industry Scale Manufacturing Plant in Taiwan

Table 49: Overview of Pilot Scale Manufacturing Plant in Yangzhou

Table 50: Overview of the equipment in the quality control laboratory of Taiwan plant

Table 51: Wuxi Biologics’ manufacturing footprint and global locations

Table 52: Facility highlights of Enzene’s Manufacturing plants in Pune

Table 53: Facility highlights of Intas manufacturing facility

Table 54: Pipeline pf Plasma derived products

Table 55: Pipeline of Intas’s Biosimilars

Table 56: Progressive pipeline of products in the manufacturing facility

Table 57: Facility highlights of Kemwell’s manufacturing plant in Banglore

Table 58: Type and batch sizes of bioreactor used in Kemwell’s facility

Table 59: Liquid vial and lyophilised vial capacity; Kemwell Bipharma

Table 60: Equipment installed in Kemwell’s facility and their providers

Table 61: Kemwell’s Product pipeline and their stage of development

Table 62: Facility highlights on Stelis Biopharma’s Banglore facility

Table 63: Breakdown of Stelis Biopharma’s facility size into each space of the plant

Table 64: Process optimisation and capabilities for the two expression systems in Stelis Biopharma’s facility

Table 65: Drug substance manufacturing features and the respective expression systems in Stelis Biopharma’s facility

Table 66: Equipment used in Stelis Biopharma’s bioprocessing value chain and their provider

Table 67: Stelis Biopharma’s Fill and Finish Equipment and their features

Table 68: Investors of Stelis Biosource

Table 69: Services offered for large molecules at Syngene

Table 70: Cell line development, Process development, analytical development and product characterisation; Syngene

Table 71: Future expansion plans; Syngene

Table 72: Highlights of both Songdo and Osong manufacturing facilities: Binex

Table 73: Binex’s Songdo facility milestone timeline

Table 74: Binex’s Osong facility milestone timeline

Table 75: Various fill and finish systems employed and Binex’s capacities

Table 76: Process Technologies used in the various stages of development in Binex’s facility

Table 77: Types of products manufactured for their clients

Table 78: Products currently in the R&D pipeline in Binex’s facility

Table 79: Number of Batches of Drug Substance and Drug Product Manufacturing completed in Binex’s facility

Table 80: GMP inspection table for Binex

Table 81: Facility Highlights on both plant 1 and plant 2; Eubiologics

Table 82: Services offered by Eubiologics

Table 83: Fill and Finish capabilities of Eubiologics

Table 84: Type of bioreactor and batch sizes used in each of the expression systems in Eubiologic’s facility

Table 85: Equipment used in Eubiologic’s plant 1 and plant 2 in both the expression systems

Table 86: Bioprocessing equipment used across the Eubiologic’s value chain and their providers

Table 87: Facility highlights of Hanmi Pharma

Table 88: Annual Manufacturing Capacity; Hanmi Pharma

Table 89: Bioprocessing tools and equipment used by Hanmi ad their solution providers

Table 90: Production building 2 facility size; Hanmi

Table 91: Facility highlights of Kolon Life Science’s B1 and B2 plants

Table 92: Facility Size of both plants in square ft: Kolon Lifesciences

Table 93: Equipment used in the bioprocessing value chain for B1 facility and their providers

Table 94: Equipment used in the bioprocessing value chain for B2 facility and their providers

Table 95: Facility highlights of Samsung Biologics’ three manufacturing plants: Samsung Biologics

Table 96: Bioreactor sizes and their respective stage of production for each of the manufacturing plants: Samsung BioLogics

Table 97: CMP1 and CMP2 details; Samsung Biologics

Table 98: Drug Product manufacturing for plant 1 and 2: Samsung BioLogics

Table 99: Equipment used by their manufacturing plant and its provider: Samsung BioLogics

Table 100: Facility highlights of AGC Biologics

Table 101: Facility Highlights of Yokohama facility in Japan: Hitachi Chemical Advanced Therapetuics

Table 102: Management team of Medinet

Table 103: Facility highlights of Takara Bio

Table 104: Board Members of Takara Bio

Table 105: Case Study 1:293- cell bank

Table 106: Case study 2: E.Coli- cell bank

Table 107: Contractors of Takara Bio to build their CGCP

Table 108: Progress of Takara Bio’s main projects

Table 109: Services offered by Esco Aster

Table 110: Facility highlights of Lonza AG

Table 111: Facility highlights of KGM

Table 112: Bioprocessing tools, technologies and equipment used by KGM

Table 113: Facility highlights of LuinaBio

List of Figures

Figure 1: Country-wise breakdown of CMOs

Figure 2: Proportion of facilities built between 2005 to 2020

Figure 3: Country-wise analysis of type of bioreactor used

Figure 4: Type of Bioreactors Employed

Figure 5: Country-wise breakdown of Process technology used

Figure 6: Process Technologies Employed: Batch vs Continuous

Figure 7: Percentage of expression systems

Figure 8: Country-wise breakdown of expression systems used

Figure 9: Facility Investment in USD millions

Figure 10: Pricing competitiveness from 1 to 10 of companies

Figure 11: Facility size of the companies in square metres

Figure 12: Number of manufacturing versus non- manufacturing employees in each company

Figure 13: Main Line of Businesses: Eirgenix, Taiwan

Figure 14: Milestones Achieved: Innovent Biologics

Figure 15: Bioprocessing equipment inside Chime Biologics’s manufacturing facility

Figure 16: Bioprocessing technologies inside Chime Biologics’s manufacturing facility

Figure 17: Bioprocessing equipment in Chime Biologics’s manufacturing facility

Figure 18: Bioprocessing technologies in Chime Biologics’s manufacturing facility

Figure 19: Summary of services offered from drug discovery to commercialisation; CMAB Biopharma

Figure 20: Eirgenix’s commercial facility

Figure 21: CDMO services offered by Eirgenix

Figure 22: Capacity of Eirgenix’s Hsnichu Biologics Plant

Figure 23: Eirgenix’s mammalian and microbial manufacturing units

Figure 24: External look and interior design of Innovent Biologics manufacturing facility

Figure 25: Process technologies of JHL manufacturing facility

Figure 26: Progress on ADC validation and research at MabPlex

Figure 27: Elaboration on the services offered for Protein Characterisation; Mycenax

Figure 28: Process Technologies Used by Mycenax

Figure 29: Bioprocessing technologies and equipment in Mycenax’s bioprocessing facility

Figure 30: Different technology platform in Mycenax’s bio-manufacturing facility

Figure 31: Product Pipeline eat each scale of Production; Mycenax

Figure 32: Regulatory approval timelines of Mycenax’s bio-processing facility

Figure 33: Mixing System by Yingde Biology

Figure 34: Single Use Bioreactor: GE

Figure 35: ADC Platform for the R&D lab, Pilot and Production plant; CP Guojian

Figure 36: Manufacturing area in the GMP facility

Figure 37: Core technology of cell therapy manufacturing; Unicocell

Figure 38: Facility scale-up and development timelines of United Biopharma

Figure 39: Exterior outlook of plant in Taiwan. Source: United Biopharma

Figure 40: Exterior outlook and bioprocessing equipments in plant in Yangzhou

Figure 41: Global manufacturing sites of Wuxi AppTec

Figure 42: Manufacturing sites of WuXi ATU in China

Figure 43: Overview of services offered by WuXi ATU

Figure 44: Their footprint in Asia; WuXi Biologics

Figure 45: High-Impact Innovation: Concept to Market; WuXi Biologics

Figure 46: Late-stage development program contract consideration

Figure 47: Wuxi Biologics Site in Wuxi City

Figure 48: WuXi’s SUBs scaling out to meet demands

Figure 49: Scale Out using 2,000L Single use bioreactor; WuXi Biologics

Figure 50: Products manufactured and Projects in their pipeline; WuXi Biologics

Figure 51: R&D facility unit 1

Figure 52: cGMP Production Facility in MIDC, Chakan (Unit I) Pune, India

Figure 53: Manufacturing Plant in MIDC, Bhosari (Unit II), Pune India

Figure 54: Bioprocessing Technologies in E-Coli Manufacturing Unit

Figure 55: Bioprocessing Equipment in E-Coli Manufacturing Unit

Figure 56: Bioprocessing Technologies in E-Coli Manufacturing Unit

Figure 57: Bioprocessing Tools in E-Coli Manufacturing Unit

Figure 58: Bioprocessing equipment in Mammalian Manufacturing Unit

Figure 59: Bioprocessing technologies in Mammalian Manufacturing Unit

Figure 60: Stelis Biopharma’s facility expansion

Figure 61: Syngene’s mammalian facility

Figure 62: Syngene’s Viral testing plant

Figure 63: Overall Organisation Chart for Binex

Figure 64: Timeline for the whole process; Binex

Figure 65: Process flow from cell line development to manufacturing

Figure 66: GMP Manufacturing, manufacturing diverse types of biologics; Binex

Figure 67: Summary of their drug product manufacturing process flow

Figure 68: Overall layout of plant 1 in Chuncheon-si, Gangwon-do

Figure 69: 10,000L Fermentation/Recovery; Hanmi Pharma

Figure 70: For Hanmi’s Proprietary Long-Acting Protein Conjugate Technology

Figure 71: Prefilled syringe filling line; Hanmi Pharma

Figure 72: Services offered by Kolon Life Sciences

Figure 73: A closer look into the Process Development services offered; KLS

Figure 74: Equipment used in the facility; Kolon Life Sciences

Figure 75: Equipment used in the Quality Control area; Kolon Life Sciences

Figure 76: Services provided by Samsung Biologics

Figure 77: Graph of Samsung’s performance at cell line development

Figure 78: Their performance shift from cell line development to Process development

and during a change in media

Figure 79: Timelines from cell line development to IND; Samsung Biologics

Figure 80: Flask culture for CMP1 and 2

Figure 81: Approvals over the years; Samsung Biologics

Figure 82: Yokohama Plant; Hitachi Chemical Advanced Therapeutics Solutions

Figure 83: Hitachi: Counter-Flow Centrifugation System

Figure 84: Hitachi Equipment found in the development room in Hitachi

Figure 85: Medinet developing commercialised regenerative medical products/ investigational products

Figure 86: Medinet’s Shinagawa CPF building layout

Figure 87: Technologies adopted by Esco Aster

Figure 88: Roller Bottle Technology used in PT Kalbio’s Manufacturing Plant

Figure 89: Robotic Technology @ PT Kalbe’ Facility

Figure 90: Automated Chromatography Equipment: PT Kalbe

Figure 91: R&D Manufacturing Suites of TCELS

Figure 92: Control of apheresis collections through five modules; CPTL

Figure 93: Clinical trials extended to Australia

Figure 94: LuinaBio Facility Layout

Figure 95: Cost comparison between USA and Australia for early phase trials

Single – User Access

This license grants the right of use of the purchased report to a single recipient only. You may access the material on your computer, as and when required, for your own personal use.

Multi – User Access

Upto 3 users: This license grants the right of use of the purchased report by upto 3 users of the same firm/enterprise.

Corporate Access

Unlimited user access (Within your organization): This license entitles the buyer of the report to share, distribute the report (either full or in part) with other employees of the same firm/enterprise. The report may be accessed by any employee of the enterprise and there is no limit on the number of users.

Additional information

| User Access | Corporate Access, Multi – User Access, Single – User Access |

|---|

Reviews

There are no reviews yet.